Khukuri of the Month

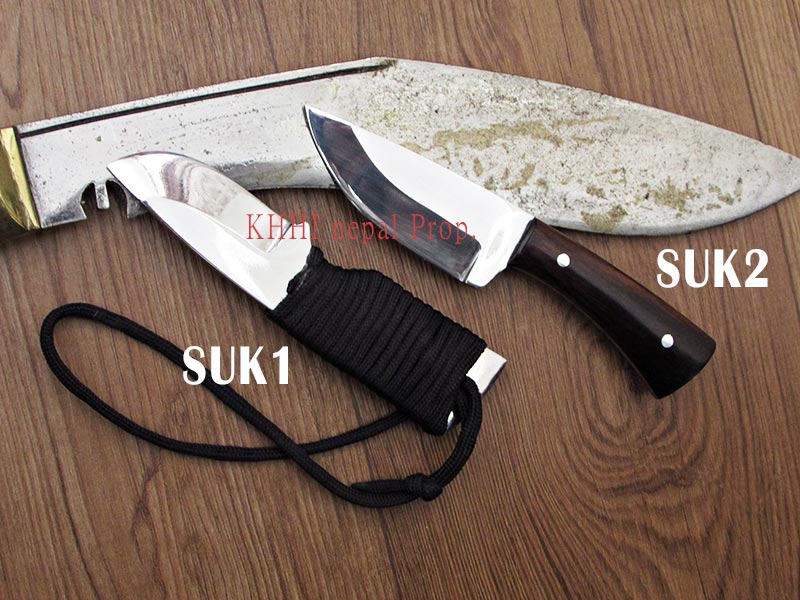

Blade Size (in): 2.5 in (SUKx 1)

Weight (gm): 100

USD 17.99

KHHI Quality & Our Specialty (Why KHHI?)

- Home

- KHHI Quality

the Excellent and Innovative quality of KHHI nepal

Knives forged to serve; made to last...

a genuine khukuri company; a maker at its best; the QUALITY and PRODUCTION activities

A simple statement and the truth, a real company dedicated to creating excellence. The Khukuri House, KHHI Nepal was established with an objective to promote the existence of khukuri, improve its quality and give khukuri worldwide recognition as a national knife of Nepal and the formidable weapon of the brave Gurkhas.

Everyone from craftsmen to personnel from the production unit works hard and sometimes round the clock tirelessly to produce quality Khukuri that would not only serve a buyer effectively but would also earn respect and admiration from the user. Genuine effort is made to keep up the originality and also give a touch of modernization to this marvelous piece of craftsmanship that would live up to the legacy and fame of the khukuri that it carries and appeals to the world. We, the maker, at KHHI put in our every effort to produce the very best quality and give excellent services to achieve what we have envisioned. Our vows to bring worldwide recognition and respect to the historic Kukri Knife by providing the highest quality khukuri blades to our potential.

KHHI uses the finest and strongest raw materials that are locally available and some are also imported from India. Raw materials are checked, re-checked, and selected before they are finally put to use. Craftsmen then do what they do the best; expertise within that has been passed down to them from generations; they turn raw material into a real masterpiece. The finished products are also checked and tested several times before they are finally approved for selling and exporting. The Quality Controller, Production Supervisor, and the Managing Director himself test the quality before it proceeds for sales and shipping.

This is why we are able to give the exclusive 1 YEAR GUARANTEE & LIFETIME WARRANTY in all our kukri/knives like no other companies.

Excellent exclusive high quality, original, handmade khukuri (kukri knives) of KHHI Nepal where discarded high carbon steel is converted into master piece. Best raw materials, hc 5160 52100 steel, skilled Kamis are used to making our khukuri/kukri knives. Real/direct manufacturer/maker of all types of traditional Nepalese khukuris and original Gurkha Army kukri

- Intro >>

- KHHI Factory >>

- KHHI Khukuri (Quality and Making) >>

- The Kamis (Craftsmen) >>

- Originality >>

- Prices and Varieties >>

- CNC Machine@ KHHI (Advanced & Modern Making) >>

- Primitive Making @ KHHI (unit 2) >>

- KHUKURI GALLERY/SMALL MUSEUM @ KHHI (Unit 2) >>

Shown below are some of the activities that happen in KHHI Nepal when it comes to production and quality control.

- GENERAL >>

- PRODUCTION >>>

- POST PRODUCTION >> Quality Control/Test

- PRE SHIPPING >> "BLADE" (the final quality)

- PRE SHIPPING >> "HANDLE"

- PRE SHIPPING >> "Packaging

GENERAL >> Raw materials/Stock/Tools

STEEL: High carbon 5160/52100 steel is used and considered to be the best and perfect to make all kukris/knives.

STEEL: High carbon 5160/52100 steel is used and considered to be the best and perfect to make all kukris/knives.

Handle Materials: Various natural materials (Horn/Wood) are used for making kukri handle.

Handle Materials: Various natural materials (Horn/Wood) are used for making kukri handle.

Domestic Tools: Basic Traditional Domestic tools used while making Khukuri/knives are selfmade by the Kamis/blacksmiths.

Domestic Tools: Basic Traditional Domestic tools used while making Khukuri/knives are selfmade by the Kamis/blacksmiths.

Production Raw Materials: High-quality raw materials available in local market

Production Raw Materials: High-quality raw materials available in local market

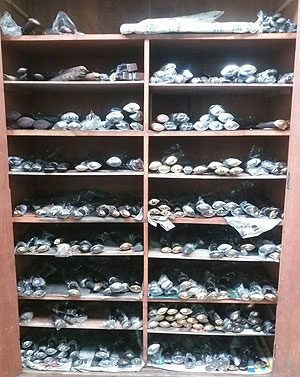

Stock: Finished khukris/knives in stock waiting to be shipped

Stock: Finished khukris/knives in stock waiting to be shipped

Khukuri Sheath/Scabbard (Dabs): large kukri stock sheaths

Khukuri Sheath/Scabbard (Dabs): large kukri stock sheaths

PRODUCTION >>

Steel Billet: The first stage of forging, 5160/52100 billet. Cutting the basic shape of a blade

Steel Billet: The first stage of forging, 5160/52100 billet. Cutting the basic shape of a blade

Forging Hammering (fala hannu): Billet (the fala) is forged and hammered to turn into the desired shape and size of the blade

Forging Hammering (fala hannu): Billet (the fala) is forged and hammered to turn into the desired shape and size of the blade

Grinding: Stone grinding in progress to get the perfect shape of the blade, grinding helps the blacsmiths to get the exact shape and pass quality test

Grinding: Stone grinding in progress to get the perfect shape of the blade, grinding helps the blacsmiths to get the exact shape and pass quality test

Finishing/polishing (whitening): Raw kukri is finished (polished) by capabale hands

Finishing/polishing (whitening): Raw kukri is finished (polished) by capabale hands

Dab (sheath) makers: Dabbe in action, the scabbard dept. "Dapwala or Dabbe" Bare hands and basic tools go together flawlessly to create something very fine and functional carriers

Dab (sheath) makers: Dabbe in action, the scabbard dept. "Dapwala or Dabbe" Bare hands and basic tools go together flawlessly to create something very fine and functional carriers

Dabbe at Work

Dabbe at Work

POST PRODUCTION >> Quality Control/Test

Marking defects /flaws: Defects if any are checked, marked and sent back to fixing

Marking defects /flaws: Defects if any are checked, marked and sent back to fixing

Testing the fitting: Fitting is tested over and over. Smashed in floor time and again.

Testing the fitting: Fitting is tested over and over. Smashed in floor time and again.

Hardness HRC: Hardness of the edge is tested by both; hrc tester files and 5" pit saw file.

Hardness HRC: Hardness of the edge is tested by both; hrc tester files and 5" pit saw file.

Weighing: Checking the right-required weight. The kukri must come withtin its official weight otherwise rejected.

Weighing: Checking the right-required weight. The kukri must come withtin its official weight otherwise rejected.

Straightness: Spine and edge are properly checked for accurate straightness.

Straightness: Spine and edge are properly checked for accurate straightness.

Checking Straightness

Checking Straightness

Checking the Finishing : Finishing is thoroughly checked to get the maximum output

Checking the Finishing : Finishing is thoroughly checked to get the maximum output

Checking the Finishing

Checking the Finishing

PRE SHIPPING >> "BLADE" (the final quality)

Hand engraving Trade Mark is done by KHHI to recognize its superior quality and to differentiate the khukuris from others found in the market. The TM officially claims that it is the production of KHHI and something KHHI is proud of and will hold responsible should there be any quality issue. The TM's sign is actually the appearance of the front line of the symbolic notch of a Khukuri.

Hand engraving Trade Mark is done by KHHI to recognize its superior quality and to differentiate the khukuris from others found in the market. The TM officially claims that it is the production of KHHI and something KHHI is proud of and will hold responsible should there be any quality issue. The TM's sign is actually the appearance of the front line of the symbolic notch of a Khukuri.

Edge Testing: Khukuri's edge is thoroughly inspected for any bent or breaking. Horn which is 10 times harder than wood is whacked several times by the edge. Here the khukuri must perform well and satisfy the inspector.

Edge Testing: Khukuri's edge is thoroughly inspected for any bent or breaking. Horn which is 10 times harder than wood is whacked several times by the edge. Here the khukuri must perform well and satisfy the inspector.

Straightnes: Final checking of straightness (allignment) of spine and edge after finishing.

Straightnes: Final checking of straightness (allignment) of spine and edge after finishing.

Sharpening: Sharpening and stroping to the max.

Sharpening: Sharpening and stroping to the max.

Paper Cut Test: Checking the sharpness of the blade.

Paper Cut Test: Checking the sharpness of the blade.

PRE SHIPPING >> "Handle"

Handle Finishing : One of the steps to get out the optimum finishing; Scrubbing handle by fine grit sand paper

Handle Finishing : One of the steps to get out the optimum finishing; Scrubbing handle by fine grit sand paper

Fixture Finishing: Finishing and polishing of the sheath's fixture/s

Fixture Finishing: Finishing and polishing of the sheath's fixture/s

Sheath Polishing: All leather sheaths are well polished according to its color for better look and to keep the leather fresh and lasting.

Sheath Polishing: All leather sheaths are well polished according to its color for better look and to keep the leather fresh and lasting.

PRE SHIPPING >> "Packaging"

Photos prior to Shipping: Few shots of each kukri being shipped are clicked for future record and reference, moslty used for shipping insurance, and solving conflicts.

Photos prior to Shipping: Few shots of each kukri being shipped are clicked for future record and reference, moslty used for shipping insurance, and solving conflicts.

Oiling: Oiling the blade and handle tang before packing and shipping to prevent oxidization and further rusting. Any motor oil would do.

Oiling: Oiling the blade and handle tang before packing and shipping to prevent oxidization and further rusting. Any motor oil would do.

Plastic Packing: Blade and Handle including steel fixture and tang is carefully plastic wrapped before shipping to protect from dirt, rust, stain and to keep it new and fresh.

Plastic Packing: Blade and Handle including steel fixture and tang is carefully plastic wrapped before shipping to protect from dirt, rust, stain and to keep it new and fresh.

Plastic Packing

Plastic Packing

Paper Packing: After all work is done on a khukuri it is wrapped by KHHI's official Lokta paper. Blade and sheath and accompanying knives (if any) are packed seperately to avoid rusting. The blade's tip is heavily taped from outside to avoid any damage

Paper Packing: After all work is done on a khukuri it is wrapped by KHHI's official Lokta paper. Blade and sheath and accompanying knives (if any) are packed seperately to avoid rusting. The blade's tip is heavily taped from outside to avoid any damage

Weighing (shipping weight): The kukri is weighed and its name and weight written on the packing paper prior to forwarding it to the shipper. Shipper then does all the legal paper works and final safety box packing then ships to the destination

Weighing (shipping weight): The kukri is weighed and its name and weight written on the packing paper prior to forwarding it to the shipper. Shipper then does all the legal paper works and final safety box packing then ships to the destination

Kamis, Khukuri, Quality & Value for money makes KHHI so special >>

THREE things that make KHHI Nepal so special … we are GENUINE, HONEST and CREATIVE.

Khukuri forging is our passion, we not only make kukris for the sake of selling but for the love of art, for the pride of our country and mostly for that deep connection of transferring a hard core steel into a khukuri that our craftsmen give life to. The aim of reaching out to people to make khukuri known along with the history for Gurkhas and beyond has always been our main goal. KHHI is so special as it gives profound depth to the conservation of Khukuri and the age old culture of forging this knife. Furthermore, there are few important things in KHHI that makes the whole company different, lively and so special.

KHHI Factory

KHUKURI HOUSE HANDICRAFT INDUSTRY is the first Khukuri House that is established inside the prestigious Patan Industrial Estate of Nepalese Government. Having its own factory in the heart of capital city, residing within government periphery and fully registered under Small cottage industry of Nepal makes KHHI special. The main objectives are to standardize the khukuri industry that has been running locally in grassroots level, to compete with the international market, give the best possible products and services and to provide the craftsmen with better opportunities, facilities and place to grow as blade smiths. We also target to fame and educate people round the globe about the legendary knife and to conserve for the next generation.

KHHI Khukuri (Quality and Making)

Khukuri for KHHI is not just a khukuri, its an art that only few chosen ones can forge, it is the pride of the country and the Gurkhas who serve/ed other countries with valor and dedication. It’s the identity of Nepali, Gurkhas and treasure of the country. So KHHI stands strong to retain the making and reputation of khukuri alive. Our khukuris are made from high quality raw materials that go under scanner, made by world class makers after properly training them and final product is repeatedly checked until it meets our strict parameters. Manufacturing is well supervised and made sure its not only made by great skill and hard work but also enough love and care is put into each blade. Then the finished ones go through rigorous quality check before its called FIT to be sold or get shipped. We proudly say that we put our heart and soul in the blade to make it come alive.

The Kamis (Craftsmen)

Bishwakarma (BK) or Kamis are born kukri makers. It’s a skill, tradition and honor passed down from one generation to another. Its in the blood by birth so to speak. KHHI Nepal has best set of Kamis to undertake the making job and needless to say, magic and miracle happen in the forge place. A work like forging hard dead steel is a very laborious, time consuming and highly demanding job which is very well executed to perfection with so much love, care and passion by our makers. It takes 3 craftsmen 3 whole days to come out with one single quality kukri. They accomplish the task with immense respect towards their work, with pride and self confident. We are very proud of our Kamis as they are the soul of the company.

Originality

KHHI Nepal is a company that strongly believes in its ability and giving nothing but the best. It is original, authentic and dedicated house that knows what it is doing. Everybody is hard working, passionate, creative and very pleased to offer and deliver the optimum outcome. Such is the air in the company. We pursue to work towards giving priority to self-innovation and pure originality. It has always been the main focus from the day of establishment till this moment. Products’ designs and features, its photos and images, websites’ layouts and presentations, services and offers, contents and literatures, concepts, planning and implementation of ideas and vision have always been KHHI’s own finding and invention hence we proudly say we are 100% ORIGINAL. We feel very proud to mention that we are strongly inclined towards our company’s objectives and ethics and strive towards maintaining its high standards.

WARNING !! Being a pioneer in Khukuri industry has brought us a long way through thick and thin. In one hand, it gives us immense pleasure to show people the way towards great entrepreneurship and showcasing the art of khukuri and how it’s done. Whereas on the other side, the pain of seeing the crippled market with imitation and back stabbing is something KHHI gets disturbed and discouraged. We therefore solemnly urge our buyers and well-wishers to be aware and be extra cautious when buying online. There are companies pretending to be us and selling imitations (fake), have used our write-ups, pictures and designs just to make some fast and easy money. These people are disgraced to the khukuri community and whole world. We are at the moment exploring copyright laws so that these fake companies do not copy us and not be able to cheat any buyers. Having said that, Nepal does not have strong copyright law in terms of online business and governance is very weak and slow. Yet we are affiliated to many organizations and working towards making the internet safe and sound place to buy from for you all.

Prices and Varieties

Wildest Range of Variety in Unbelievable Prices makes KHHI special

Pricing

KHHI ensures that products it sells come at reasonable costs, and the team is always exploring different ways to cut down costs without compromising on the quality. The operation team buys raw materials in bulk, implements effective management system to control costs and monitor expenses so that cost per unit decreases and hence can be offered at competitive prices. KHHI produces more than 400-500 high quality kukris in a month which makes us the largest kukri manufacturer in Nepal, producing kukri ranging from USD 20 onwards. Two things that conflict at KHHI are HIGH quality LOW price.

Variety

Besides the quality and price, variety is another important factor that attracts a customer towards a seller. KHHI Nepal over the years has achieved a milestone to come with what we call as the “widest and wildest” range of products that is never seen or heard of, and something that is very hard to resist. Preparing a large variety with the heart and hand at creativity, quality, market demand and perspective is a challenge that KHHI dares to undertake. It offer various types from army to village, historic to modern kukris, decorative to working utility, sacrificial to showpieces, mini to giants and some unique and innovative designs that matches the taste of any hardcore users. KHHI also has advanced “Design” unit where customers can request for custom-design orders of their choice. Likewise KHHI’s prompt customer service and support even after sales add intensity to the company hence we have more than 90% returnee loyal customers always supporting us. Someone aptly said “Variety is the spice of life”, hence KHHI keeps working rigorously to add up new designs and to further widen its product range so there is anything and something for everybody and anybody.

CNC@ KHHI

Introducing CNC (computer numeric control) technology in the company has been a BIG leap to further boost its product, standard and image. We have come a long way from being a small retail shop to a branded company and our CNC Wing just adds beauty and depth to our yet another accomplishment. We see this as an example of an inspirational journey for all small companies who aspire to do big and leave its mark forever.

As a company we have grown and flown with the ever changing time, technology and culture. It is our strong belief that one must grow and explore but also maintain the root, your identity at the same time. We did modernized ourselves but did not leave our tradition. We bought cnc machines yet we held to the hammers and forge. Our CNC machines are especially used for custom-design works and ultra modern kukris and knives that require full accuracy and precision, and to also save time and money. KHHI can fully offer professional services and deliver any demand on custom pieces than any other makers.

We use CNC for >>

- To make custom-design knives and modern kukri-knives that need specific and precise measurements

- We only do the profiling thru CNC machines and rest of the making is all done by hand by our skilled kamis

Lastly, we are very proud to announce that we are the only company in Nepal and probably in the world to use the CNC technology to execute the makings effectively, efficiently and economically.

Primitive @ KHHI (unit 2)

From the traditional way of making khukuri to using CNC for precision making, KHHI Nepal has given all out. It has vastly grown as a company and everyone associated with it. Now, it is time that we give back to khukuri world!

When we talk about specialty of a manufacturing company, there will be lot of good things that company does to prove its worth. As mentioned above, KHHI has so many aspects that show how it has emerged as one of the most special manufacturing company. However KHHI as a progressive company is not limited or satisfied there only. To push further ahead it has now opened it’s another wing “Primitive Making (Wing)” where making of kukri is taken to a different level, in which everything is bare hand, raw skill and natural materials all the way.

“Primitive Making” in KHHI’s unit 2 was opened to all not entirely for the purpose of business but mostly for conservation purpose. Khukuri making has evolved over the decades with time, demand and circumstances. We still use the traditional method of forging and related yet power tools and grinders are also used together to accomplish the making. This was certainly NOT the case centuries back. There was no electricity (main source) so how was the making possible?? How was khukuri made then?? What did the makers have to go thru?? KHHI went for rigorous research and exploration to remote villages of Nepal to figure out the answers and we were fortunate enough to meet old folks who knew exactly what we wanted. They helped us with information, process and age old techniques, one even agreed to come and help us set up the Primitive Making. After that there was no looking back….

KHHI primitive is a conservation project. Thru it we want to keep alive the process and spirit of making kukri when there was no basic necessities, we want our children and our future generation to see and connect with the basics, to admire the simplicity, the skills, hard work and enthusiasm put forward by the makers and overall want to preserve our piece of history to the new coming generations.

KHUKURI GALLERY @ KHHI (Unit 2)

The Gallery is another specialty and important accomplishment of KHHI Nepal. It adds so much value and depth in the company as this is another conservation campaign like the ‘Primitive Making” done to save the khukuri and its legacy. The objective here is to provide anything and everything on/about the khukuri to the general public. We aim to educate and aware people about the significance, development, history, conditions and various information related to khukuri.

Khukuri is more than just a knife... it is our national pride, an icon and more importantly our identity hence a substantial action to preserve was necessary which is well addressed by the opening of our gallery. Worse, it is a handmade historic article and like any handicraft khukuri has also been victim of modernization, negligence and various business issues due to which such conservation step was must and we being a pioneer took the responsibility to sustain khukuri and its legacy to the public and for the new upcoming generations.

Whenever you are in Nepal please feel free to visit our UNIT 2 which has the Primitive Making and Khukuri Gallery. We invite you to spend as much time as possible and come with all your friends and family. Enjoy and Learn about the world’s most famous, functional and feared knife.

All these qualities and specialties make KHHI Nepal the no.1 khukuri company of the world. We promise to move forward with the same enthusiasm, dedication, energy, and intellect.