Khukuri of the Month

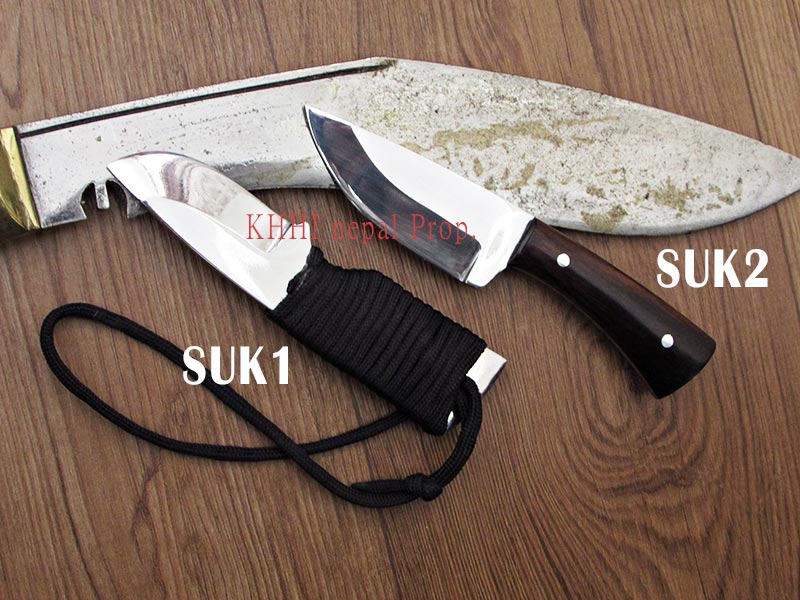

Blade Size (in): 2.5 in (SUKx 1)

Weight (gm): 100

USD 17.99

Making Of Khukuri

- Home

- Making Of Khukuri

In the majestic valley of Nepal where the mighty Himalayas rule, lives a community of artisans who practice an art passed down to them from generations of their forefathers. Using simple hand tools, these masters transform surplus leaf spring into knives that know no equal. The men are called Bishwakarmas or Kamis (which in Nepali means world markers) and from their forge comes the legendary "Khukuri or Kukri"; the world’s most famous and feared knife.

The objective of this page is to show these masters at work; how they turn a piece of steel into a masterpiece, and also to make all viewers aware of the special skill, hardship, and endurance the maker has to go through to achieve his goal.

How do we make a Khukuri / Kukri Knife?

Before we go into the Making there are a few things to know about the background of the khukuri and its making.

A khukuri like any other knives has three primary sections; Blade, Handle, and Sheath. The assembly and fixing of these 3 departments make a kukri complete.

This historic blade has always been made out of high carbon steel traditionally. First, it was called the “Himalayan Steel”, the iron-ore extracted from rugged hills then came the railway track steel popularly known as "Leak Steel" and now presently the "Leaf Spring" or suspension steel of the vehicles.

This historic blade has always been made out of high carbon steel traditionally. First, it was called the “Himalayan Steel”, the iron-ore extracted from rugged hills then came the railway track steel popularly known as "Leak Steel" and now presently the "Leaf Spring" or suspension steel of the vehicles.

Similarly, the partial water quenching to harden the edge has always been a common but skillful practice from the classic days till now. Kukris are never tempered also right from the old eras. Most kukri knives have convex edge for durability and strength since the blade is objected for hacking.

Speaking of the handle, it used to be walnut, now rosewood is more common and water buffalo horn for the army types. Likewise, RTT (rat tail tang or Parowal) has always been the preferred handle type.

Similarly, the leather sheath also evolved over the years and has been heavily affected by the ever changing time. Treated leather that is achieved from the painstaking homely process is now replaced by modern leather supplied by industries that go thru their own leather treatment facility. Sheaths of today are much simpler and less grand than it used to be.

The two accompanying knives, Karda and Chakmak, have almost extinct these days. People hardly value it.

See our world-class Kamis (Blade smiths) in action!! Various Kukri Making methods at KHHI nepal

'The Khukuri House' has been making high quality kukris and knives since 1991. We undertake THREE methods of making which are briefly explained and captured in the videos below. Come witness the brief step-by-step process of each method.

1. TRADITIONAL method >>

Blacksmiths work in coordination with conventional machines. Forging, hammering, quenching, grinding are the key steps.

2. PRIMITIVE method >>

Dedicated Kami/blacksmith with great skill, hard labor, and max. sweat all the way. The method used centuries ago. Learn more about primitive khukuri making and products available exclusively at KHHI.

3. ADVANCE method >>

CNC machines are used to execute perfection and precision in the outcome. Mostly used for making custom-design and ultra-modern knives.

Below are major steps in Khukuri (kukri knife) making process..

Forging the knife by hand power (beating and hammering )

Water Quenching Kukri Knife, the most important step in Khukuri making... MAKE IT OR BREAK IT stage

Kukri knife Heat Treatment (local hardening) at KHHI nepal

Our heat-treatment is done in a basic and traditional way but performed very carefully and skillfully. The partial water quenching (differential hardening) technique is adopted which is very effective for large knives like kukris that are made from high carbon steel like 5160 and 52100. The heat treating goes in a natural process from Forging to Finishing. The same method that has been in practice for generations and something that is synonymous to a kukri is undertaken by KHHI nepal. Here the objective is to respect and continue with the reputation, exceptional blade smith and legacy of our forefathers (Kamis).

The 3 crucial steps of the heat treatment go naturally...Normalization, Quenching, and Tempering.

Normalization:

Maker picks up at least 4 kukris at a time which is made one at a time. First the 1st piece is forged and hammered and put to rest then 2nd one picked up and so forth. This method is intentionally done to naturally normalize each piece in the making process.

Quenching (hardening):

The kukri is evenly heated on all surfaces till it reaches the critical temperature (cherry red color) in a charcoal furnace. Then it is taken out of the fire and quickly the edge is gently scrubbed by a file to clean it. This also gives some time for air-cool for the heated blade and then room temperature water is poured all along the bevel from ricasso to tip until the maker is satisfied. He then flips over the knife and continues pouring the water. During the whole process he checks for any kind of warp that may occur due to high stress created in the blade. Finally the water is poured on the other surface of the blade as it starts to cool down further. Such partial quenching method gives optimum hardness to the edge, much less hardness to the panel and almost no hardness to the spine. This various hardness gives stiffness and softness (cushion) at the same time. This is something that has been in practice for centuries with phenomenal result. We as a maker do not even dare to change it or improve it or better it.

Tempering:

The natural process of preparing (finishing) the knife auto corrects the brittleness. The kukri goes through a series of machining steps in which enough heat is generated which in return naturally tempers the blade in each step. This eases the strain within the blade triggered by quenching and the blade becomes tough from brittle. The blade is never dipped in water, rather cooled in still air.

The above mentioned heat treatment process is deeply investigated and well tested by KHHI Nepal. Now and then we also forcefully snap off a blade or two to check and study the grain structure of the steel. The blade is thoroughly tested for edge strength, retention, deformation and flexibility. Edge is forcefully whacked in dry horn for edge strength and very hardly scrubbed against brass rod to check its springiness. Such heat treatment has never let us down and is one of the main reasons behind the success of the company. Its not only an excellent classic technique but also helps to conserve our rich blade smith that has been a major part of our history, culture and recognition.

PS: Heat Treatment in Oil is possible on request. No extra charge is applied.

Making Kukri Bolster (Kanzo)

Joining Blade & Handle of khukuri (rat-tail tang / parowal )(fascinating video)

Making of Khukuri Scabbard/ Sheath (DAP)

making a kukri sheath all by hand, basic tools, and a lot of skill by our Dap makers at KHHI.

Do visit our official Youtube channel to see more videos of the making process in our facilities. If you are in Nepal, you are most welcome to come and witness the live making and also feel free to try out your skill along with the masters.

Since 24th February 2023, on the occasion of 32nd Anniversary, KHHI has started the 'Khukuri Making Workshop' training. You can learn the old-age traditional khukuri making skills directly from the master. See the pricing and details and Book your class date today.

You can also see the photo collection of making khukuri blade, handle and sheath back in the 90's it was more traditional-painstaking and more lively.

We are extremely proud to offer our Khukuri/knives with the LIFETIME WARRANTY and thankful to all our happy customers for highly recommending and rating us (4.9/ 5 star) on Google Review.

Share